Navigating the Complexities of Building Construction: A Guide for Individuals

- Manoj Mittal

- May 27, 2025

- 9 min read

Updated: Jun 28, 2025

for the best experience, view on desktop

Constructing a building is a significant challenge, especially for individuals in India without prior experience. The journey from initial conception to final completion is filled with complexities that can be overwhelming. With over four decades as a civil and structural engineer, I have firsthand knowledge of these challenges. When I built my own house 23 years ago, I encountered numerous difficulties that deepened my understanding of the obstacles in such projects. Today, as people juggle professional and personal commitments, managing construction activities has become even more challenging. Compounding these issues are concerns like a shortage of skilled labor, declining professionalism, and a loss of trust and ethical standards. This article aims to clarify the entire construction process and propose practical strategies to empower individuals with the knowledge and insights needed to undertake projects confidently and efficiently. While my primary focus is on small-scale buildings for individuals or small businesses, the points discussed here are applicable to various types of construction.

Whether you are planning to construct a residential, commercial, industrial, or institutional building, thorough preparation is key to a smooth and successful project. I always advise my friends and relatives embarking on such an endeavor to invest time in understanding their own needs before approaching professionals and resource persons. No one understands your requirements better than you, so it is crucial to engage in deep discussions and preliminary planning before taking the next steps.

Begin by engaging in meaningful discussions with your family members, colleagues, business partners, or team members. Collectively, outline a document that clearly defines the functional and aesthetic requirements of your building. Be sure to include any constraints such as time limitations, budgetary restrictions, or specific site-related challenges. This document does not need to be perfect or highly detailed—it serves as a foundational reference to guide professionals working on your project. For better visualization, consider sketching a rough layout on paper, even if it is just a basic outline. This can significantly help architects and engineers understand your vision and translate it into a functional design. If possible, seek advice from friends or acquaintances who have recently undertaken similar construction projects. Their firsthand experiences, challenges, and solutions can offer valuable insights that may help you avoid common pitfalls.

One of the most critical steps in any construction project is assembling a skilled and cohesive team with whom you have good chemistry. A well-chosen team can significantly impact the quality, efficiency, and overall success of the project. Your first step should be to engage a knowledgeable architect or civil engineer with a strong aptitude for planning and design. They must be well-versed in building byelaws, regulatory requirements, and industry standards, ensuring compliance with all legal and structural regulations. When selecting professionals seek recommendations from friends, colleagues, or acquaintances who have recently undertaken similar projects. Compile a shortlist of potential candidates based on these recommendations. Conduct meetings and discussions with shortlisted professionals to evaluate their competence, experience, and alignment with your vision. Verify that they are qualified and registered with local regulatory bodies and professional institutions. Narrow down to one or two final candidates and request formal proposals from them. Carefully examine the scope of work and exclusions in their proposals to avoid misunderstandings later.

For smaller projects, such as residential houses, hiring a principal consultant—typically an architect or civil engineer—with a comprehensive scope of work can be highly advantageous. Their responsibilities include securing municipal approvals, ensuring compliance with local regulations, and obtaining necessary permits. They oversee the planning and design of key systems such as architectural layouts, structural frameworks, electrical configurations, plumbing networks, and air-conditioning setups, ensuring functionality and efficiency. Additionally, they prepare cost estimates to help you plan your budget effectively. The consultant also plays a crucial role in contractor selection, assisting in the shortlisting and appointment of reliable professionals for project execution. Once construction begins, they conduct periodic supervision, monitor progress, and maintain quality control, ensuring strict adherence to approved drawings and specifications. They also verify contractors' bills, ensuring transparency and accuracy in payments. Finally, they facilitate the process of obtaining the final completion certificate, ensuring that all legal and technical aspects are addressed before handing over the completed project. In a way they act as a guide for navigating the entire journey of building construction.

Since principal consultants rely on specialist consultants for specific aspects of work, it is essential that you know who they are and meet them personally. If you have reservations about any of them, discuss your concerns with the principal consultant and request changes if necessary. Open communication and informed decision-making will help ensure a smooth and well-executed project. However, for large or complex buildings, hiring specialist consultants directly (such as structural, MEP, or HVAC consultants) may provide better quality control and expertise in each discipline. In such cases, you must entrust the coordination between various consultants to either your architect or civil engineer. For medium-to-large-scale projects, a Project Management Consultant (PMC) can be highly beneficial. Their role depends on when they are hired: If engaged only for execution, they coordinate between consultants and contractors while ensuring quality, time, and cost management through on-site engineers. If engaged before construction, their services will also include Preparing bidding documents based on consultant designs Inviting tenders, evaluating them and finalizing contracts with contractors.

The Bureau of Indian Standards (BIS) provides several guidelines outlining construction service requirements for various construction services. The National Building Code (NBC) 2016 – Part 2 (Administration) also specifies the qualifications and competencies of various professionals. Further there are several standards published by Service Sector Division (SSD) of BIS particularly SSD06, SSD21 & SSD 22. Understanding these standards can help define the roles, scope, and responsibilities of each consultant effectively.

For small buildings, a single contractor may suffice. However, for multiple buildings or complex projects, hiring multiple contractors for different services may be thought of in consultation with consultants or the PMC. Once professionals and contractors are finalized, it is crucial to have written agreements with each one, outlining their roles, scope, and terms. Avoid excessive negotiation on fees—while cost efficiency matters, consultancy fees should not be the sole deciding factor unless they are significantly off-market rates. Quality and expertise should take precedence over cost-cutting measures.

Contractors are appointed only after the design, drawings, estimates, and bidding documents are finalized. The process begins with specifying your requirements to your architect or civil engineering consultant, along with relevant site data. Share your initial outline and sketches to provide a foundation for their work. Give them creative freedom to develop a thoughtful plan that meets or exceeds your expectations while remaining feasible for construction. This may require multiple meetings and iterations before arriving at a final, agreed-upon plan. Once finalized, the design will be developed for municipal approvals and detailed working drawings for execution. Simultaneously, other essential drawings—including structural, MEP (Mechanical, Electrical, and Plumbing), and HVAC (Heating, Ventilation, and Air Conditioning)—will be prepared by respective consultants. After thorough coordination and your approval, these documents will be handed over to the appointed contractor for execution.

With the drawings in place, the building's specifications—including finishes, flooring, and façades—will be determined in consultation with you. Since these choices significantly impact costs, multiple adjustments may be needed to ensure alignment with your budget. Once the specifications are finalized, the consultants or project management consultant (PMC) will prepare a detailed cost estimate. If the estimate exceeds your budget allocation, you may modify the specifications or design to achieve a better financial fit. It is important to ensure that you have provision of funds to the tune of estimated amount plus at least 10 percent for contingencies. Upon finalizing the specifications and budget, bidding documents will be prepared to facilitate contractor appointment.

Appointing a competent and resourceful contractor is a crucial step. You can seek recommendations from friends or consultants and assess credentials such as turnover, completed projects, ongoing work, recommendation letters, technical workforce, and available equipment to ensure suitability. It is always a good idea to visit some of his recent works. Keep in mind that a very big contractor for a small work and a small contractor for large or complex work is not a good idea. Once shortlisted, issue bidding documents for selection. Your principal consultant and/or PMC will assist you in this matter. For large projects formally prequalification is done before issuing bidding documents. For small works usually checking credentials and recommendations are enough.

For small to medium-sized building projects, Item Rate and Lump Sum contracts are commonly used. Item Rate contracts are simple, transparent, and flexible, allowing changes during construction, though frequent alterations should be avoided. Each work item is measured for payment, which can be managed efficiently if a Project Management Consultant (PMC) is appointed. Lump Sum contracts, on the other hand, involve the contractor quoting a fixed price based on predefined scope, drawings, and specifications. Payment stages are predetermined, making contract management smoother, but changes during construction are difficult and may lead to disputes. All drawings and specifications should be finalized before signing the agreement. Owners sometimes prefer to procure certain materials directly and supply them to the contractor, either at a set rate or free of cost. Such arrangements should be clarified in the contract beforehand. Ensure the contract includes timelines, payment methods, quality assurance mechanisms, penalties, performance warranties, retention money, defect liability period, termination clauses, dispute resolution procedures, and adherence to labor and safety regulations, along with the General and Special Conditions of the contract.

Now work on site can begin. Have the contractor prepare a project schedule using CPM/PERT or BAR chart in consultation with the PMC or consultants. If you will not be available full-time, consider appointing a representative to oversee the site. For very small projects, this may not be necessary, but frequent site visits are still advisable. Schedule regular update meetings to monitor progress and quality. Ensure that the PMC, consultants, and contractor adhere strictly to drawings, specifications, and contract conditions, Make timely payments to the contractor after bill verification by the consultants/PMC. Any changes due to site conditions, design modifications, or material substitutions must be documented in writing. Maintain direct and efficient communication to ensure smooth execution rather than focusing on fault-finding. Disputes should be resolved quickly before they escalate. Never compromise on design or quality, especially in structural integrity, waterproofing, electrical, and plumbing work, even if there are budget constraints. Avoid frequent changes, as they can disrupt workflow. While you may receive advice from friends or social circles, trust your consultants and contractor—but remain open to discussions when needed. Maintain organized records of drawings, revisions, contracts, material specifications, test reports, measurements, and payments. Document progress with photographs and videos, as they can be valuable references. Lastly, adhere to the sanctioned plan, as deviations could lead to complications in obtaining the completion certificate.

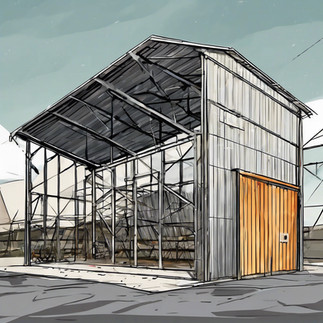

While not everyone needs to be a construction expert, having a basic understanding of technical aspects can significantly enhance quality control. A key initial step is conducting a subsoil investigation with a reputable geotechnical consultant. This assessment provides vital data for the structural engineer, enabling the design to be safe, appropriate & optimized. When it comes to concrete, sourcing ready-mixed concrete (RMC) from a trusted vendor ensures consistency and quality. For on-site production, batching plants or weigh batchers can be utilized, but RMC is generally preferable for smaller projects, as it reduces errors and ensures standardized quality in addition to convenience. Reinforcement steel must meet required grades and be obtained from reliable suppliers to have desired quality and consistency. Regular field and laboratory tests on essential materials—such as cement, steel, bricks, coarse sand, fine sand, coarse aggregates, and water—should be conducted in collaboration with engineers or Project Management Consultants (PMC). These tests confirm quality, durability, and compliance with industry standards. An often overlooked yet critical aspect of construction is curing. Proper curing significantly enhances the strength and longevity of concrete, brickwork, plastering, flooring, and other structural elements. Ensuring sufficient curing time and methods leads to a high-quality finish and lasting durability. Pre-engineered buildings can also be considered for warehouse or factory sheds or similar structures for convenience and faster construction, but it is utmost important to ensure that PEB vendors follow relevant standards.

Important Standards for Building Design and Construction are-IS-875 Part 1, 2 & 3/IS-456/IS-800/IS-4326/IS-1893/IS-13920. In addition to the above standards, the NBC, CPWD specifications, Schedule of Rates, and Plinth Area Rates are valuable resources. If you are interested, you may also explore more on YouTube. However, the final say on such technical matters should rest with the consultants. It is important to note that I am not suggesting you read these documents in detail, but you should be aware of their existence.

Building your dream structure is more than assembling materials—it is the realization of vision, expertise, and careful execution. With a team of skilled professionals, well-defined requirements, a trusted contractor, and timely payments, the path to success is set. Clear communication, swift decisions, and a commitment to quality ensure steady progress. As steel and concrete take shape, walls rise, and dreams solidify, you witness the transformation—an idea becoming reality. And when the dust settles, the scaffolding fades, and you step inside the space you once imagined, you know—it was all worth it.

Manoj Mittal – June 7, 2025, Noida

© This blog post is the intellectual property of MANOJ MITTAL. Unauthorized use or reproduction is prohibited.

An amazing article and valuable guidance have been shared by Shri Manoj Mittal ji, a highly respected Structural Consultant and Adviser. His insights offer immense support and clarity for those involved in construction activities. The depth of his experience and the practical advice provided are truly commendable, making this contribution a significant resource for professionals and enthusiasts alike..

Thanks Sir,

Rakesh Bhatt

Wholistic and very useful article Manoj on navigating the construction complexities! All important and critical elements have been covered. I can co-relate many of these being in middle of our home construction. Ethical standards, professionalism and execution delivery on time after technical design define the critical landscape of gaps.